LOLER assessments (Lifting Operations and Lifting Equipment Regulations)

The LOLER or Thorough Examination is an annual mandatory requirement under health and safety legislation for all equipment and accessories used in lifting processes under the 1998 Regulations.

Employers have a duty to ensure that any lifting equipment provided for their employees and others working for them complies with these regulations and is inspected in line with its proposed use. This thorough examination is normally once or twice a year but may need to be more or less frequent.

Whatever your working environment, our comprehensive inspections will ensure continued safety and compliance of the lifting machinery or equipment you use, maintaining safe and successful lifting operations and reducing the potential risk of injuries and fatalities.

Sophus Safety Solutions can manage your inspection requirements and ensure compliance and safety of use.

Contact Us to Discuss Your NeedsLocal Exhaust Ventilation (LEV testing)

COSHH regulations require that all LEV systems are subject to a thorough examination. They also require most LEV systems to be tested every 14 months, including all oil mist, welding fume, smoke and dust extraction units that you have on site.

This examination must be undertaken by a competent person, and the tests and reports must conform to HSE standards. The HSG258 guideline on Controlling Airborne Contaminants provides the recommended procedures to achieve these statutory requirements.

Sophus Safety Solutions can manage your inspection requirements and ensure compliance and safety of use.

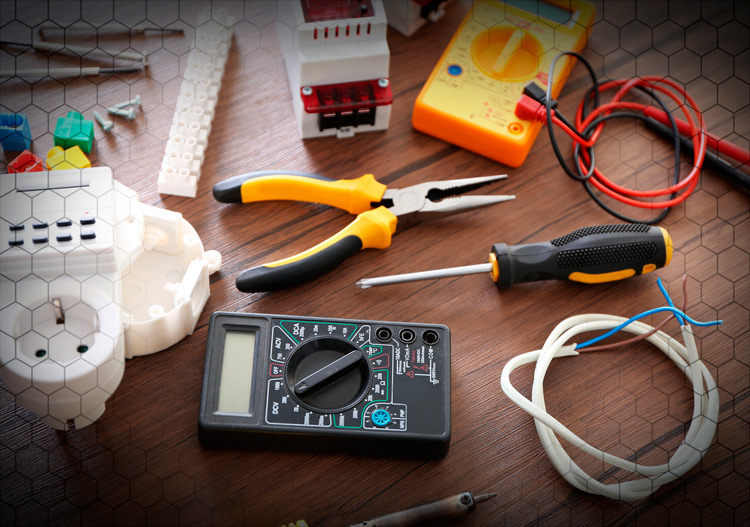

Contact Us to Discuss Your NeedsElectrical tests and inspections (PAT and fixed-wire testing)

The law does not require electrical testing to be carried out on electrical equipment, but it does require that you keep your entire electrical system safe at all times. The only effective way to do that is to have periodic testing and inspection carried out, together with action to remedy any faults found as a result of testing.

Portable Appliance Testing (PAT) is the examination of your electrical appliances and equipment to ensure they are safe for use. Many problems can be found by careful visual examination, and a regular user check (based on training and a checklist) is a good idea. However, some problems will only be identified by a combination of visual inspection and testing by a Competent Person.

Fixed Wire testing is the report and safety inspection of the electrical systems in your premises. It is known as the Electrical Installation Condition Report (EICR), previously known as the Periodic Inspection Report, and is designed to make sure that your electrical wiring is compliant with current regulations.

The necessary frequency of these tests depends on your work environment, as equipment used in a harsh environment should be tested more frequently than equipment that is less likely to become damaged or unsafe.

If an accident or fire does occur where electricity is suspected to have been the cause, it is important that you have documented evidence of compliance with the approved code of practice.

Sophus Safety Solutions can manage these all these requirements and arrange for your equipment to be thoroughly tested by a competent person frequently enough that there is little chance the equipment will become dangerous between tests.

Contact Us to Discuss Your Needs